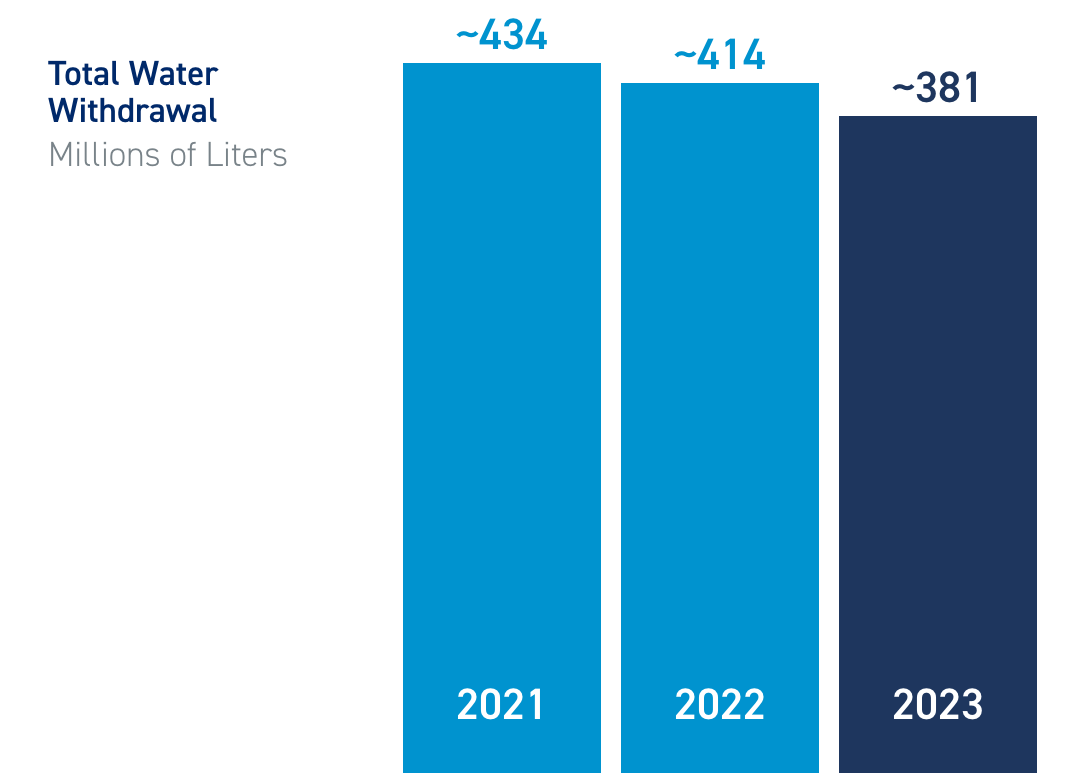

Our commitment to reducing our environmental impact includes being a responsible water and waste steward. As water availability and scarcity vary considerably from region to region, we evaluate opportunities to minimize the amount of water we consume on a local basis.

Monitoring and Reducing Water

Water is a material input and output of our production process given the nature of our products. It is a significant input for the preparation of our chemical solutions, and it is used to support production as well as cooling and cleaning. A significant portion of our water withdrawn is included in our manufactured products.

We regularly monitor our water use and pursue opportunities to minimize both consumption and contamination. Initiatives include reusing rinse waters from previous manufacturing batches and the use of high-pressure low volume devices and other water-conserving equipment for cleaning production vessels. Nineteen of our manufacturing facilities (and several R&D only facilities) treat their own wastewater before disposal.

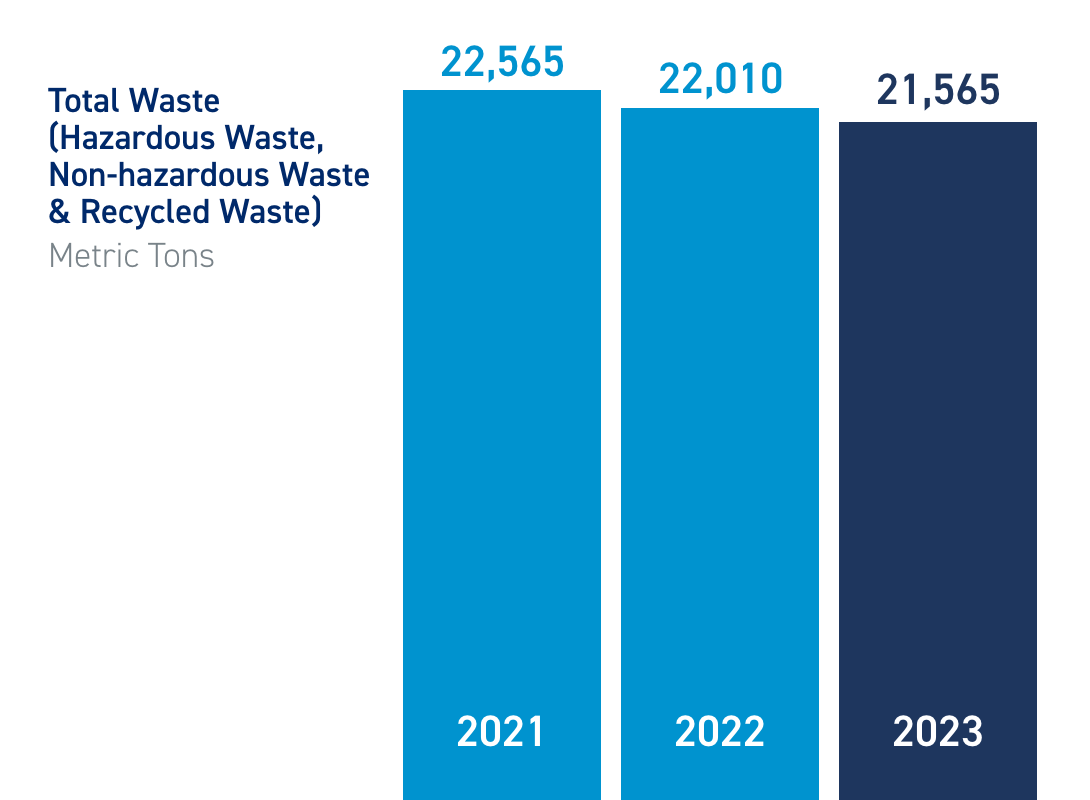

Measuring and Reducing Waste

We monitor and aim to reduce general and hazardous waste within our production operations. Many of our facilities have set specific goals and targets related to the management of hazardous waste as part of their broader ISO 14001 certified environmental management systems. Initiatives to manage waste include capturing “heels” (leftovers) of batches, which we then use in a subsequent batches, and reusing first water rinse from a tank in the production process of a similar product.

We believe our efficient use and management of materials and waste mitigate our impact on the environment while reducing our operational costs. Due to an ongoing focus on materials management in 2023, we reduced our total waste by ~2%. Our recycled waste was 11% higher, leading to a reduction in hazardous waste of ~3% and non-hazardous waste of 12% compared to 2022.